multimedia adsorbent tubes OSB LAB MULTIMEDIA ADSORBENT TUBES

Sampling Instructions for Pumps

The tubes have been cleaned and hot sealed

under a helium atmosphere to give them an extended shelf-life. Opening the transport container may result in

slight suction as the vacuum is broken.

The color dots on the cap identify preparation batch.

Do not use any solvent markers near the tubes.

Do not write on the tubes or on the transport

containers.

Do not seal the ends of the multisorbent tubes

with plugs or teflon tape.

Return tubes to their containers as received

and do not affix any labels.

Record the MB number on the Chain of Custody

form as your sample identification.

1. Calibrate and set your

pump flow rate with a calibration tube.

2. Open transport container

and carefully remove tube. Avoid

touching the ends of the tubes directly to avoid possible contamination. Latex Gloves may be worn to prevent

this.

3. Immediately cap the

transport container to prevent introducing contaminants and put it aside.

4. Make sure sample

direction is as follows:

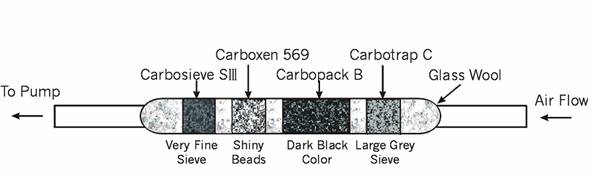

The Carbosieve SIII must be closest to the pump. Carbosieve SIII is the finest molecular sieve

in the tube.

5. Sample volumes that are

needed:

a) if a strong odour is

present - 1 Litre or less

b) if a mild odour is present

- 2 to 3 Litres (preferably 3 Litres)

c) indoor air - 5 to 20

Litres, depending on environment

OSB Lab always splits the original sample at least 1:1 before analysis

to provide a backup analysis if required.

Moisture conditioning is carried out if the sampling humidity was high

or water vapour was collected. It should

be noted on the Chain of Custody sheet if sampling is performed in a high

humidity environment or if water vapour may have been collected.

6. After the sample is

completed, remove the tube from the pump and return it to the transport

container and secure the lid tightly.

Return the tube without sealing the ends. Complete the Chain of Custody form. Sample volumes must be recorded.

7. The tubes are packed in

the transport containers with pieces of teflon cut from a sheet to prevent

breakage. The transport containers are

still fragile and need to be properly packaged for shipment to prevent them

from being crushed. Normally the exposed

tubes do not have to be refrigerated under ambient conditions.